Sierramotion Introduces an integrated Gearmotor/Robot Joint

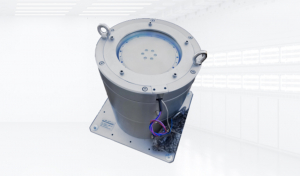

SMRT-2000 is a highly integrated package with precision zero backlash gear, servo torque motor, and absolute encoder

SMRT-2000 is a highly integrated package with precision zero backlash gear, servo torque motor, and absolute encoder

The current market for robotics is growing at a fast pace. The growth areas are mainly in collaborative robots, (“Cobots”), working with humans to improve throughput and accuracy…

The current market for robotics is growing at a fast pace. The growth areas are mainly in collaborative robots, (“Cobots”), working with humans to improve throughput and accuracy…

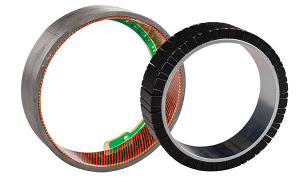

Frameless motors are used everywhere today. Every electric vehicle, hybrid vehicle, rotary stage, robot joint, gimbal, and many more advanced industrial applications use frameless motors.

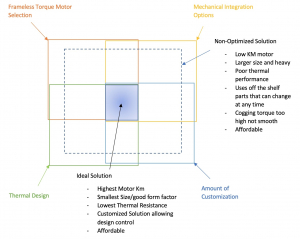

Custom motor is typically a motor that has unique features and performance specific to the application and this set of requirements is not available when the project is started.

Torque motor is a term that has been created to describe a motor that will be used mainly for torque control in a precision system.

Direct Drive has seen a re-birth in awareness and new applications over the past 20 years. Driving a shaft directly is really nothing new and has been done for over 100 years.

In this webinar, Sierramotion co-founder, Robert Mastromattei, talks about the benefits of combining direct drive motors and precision gearing for robotic joints.

This article provides five tips on how to select a direct drive frameless torque motor kit and provides system engineering requirements for the drive motor selection.