Direct drive stages can be more precise, more responsive, and very stiff dynamically. Comparing to a gear worm driven stage, the torque output will be less with direct drive. So for moving low weight things around, direct drive is probably best.

Wide range of sizes

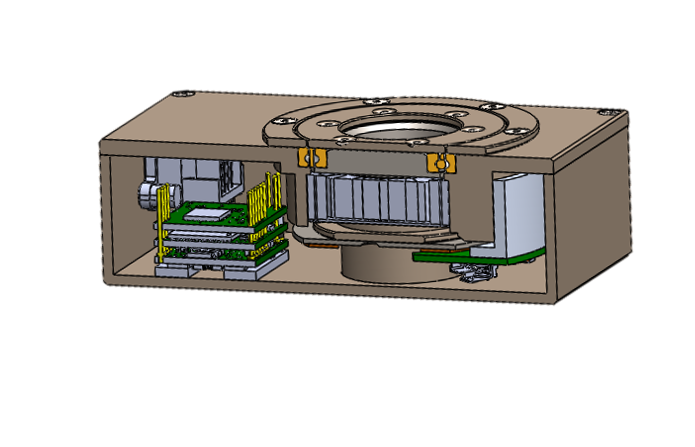

Fully customizable from large diameter short axial length to small diameter, a precision stage can be formed to the space and performance constraints.

Special materials

Many optics reside in UV environments. Material selection is critical to have UV compatibility. Special cables and exposed materials need to be carefully considered.

Low profile

Sometimes it is necessary to insert rotating optics into an existing system. A low profile precision stage can be as thin as 10mm as long as the diameter is available to locate things in plane with the optics.

Precise motion

The combination of a high resolution encoder and digital motor controller results in highly dynamic and accurate positioning or torque control.

Precision torque control

Using a direct drive torque motor with zero cogging will result in smooth operation and a level of precision beyond any geared stage or even direct drive with an non-approprate torque motor that is non-linear and has cogging torque.

Low heating

Direct drive can result in low heating by eliminating gearing and heat created. This is of course dependent on the load required. Many engineers choose off the shelf geared rotary stages with low cost stepping motors. While these may be easy to get and low cost, they can heat up to 100 C even when they are not running.

Direct Drive Mechatronic Stage Specifications

Applications in advanced electronics and optics require precision and special motion as well as operation in special environments. Sierramotion will guide you through the maze of options and help you settle on the correct design for the project. It is more important for our engineers to help customers with the right solution rather than sell them on what is available.

| Specifications | |

|---|---|

| Large Aperture | Through holes up to 80% of the outside diameter |

| Low profile | Low axial height down to 10mm |

| Smooth motion | Zero cogging options to ultimate smoothness |

| High resolution options | Encoders up to 26 bit possible 22 bit standard |

| Optional windings | Adjust to any DC or AC input voltage by changing the motor winding, not adding a transformer |

| Special materials | Whether it is a UV environment or a high temp/low temp there are options to choose from. |

| Operation in Vacuum | Adding a rotary stage to your vacuum chamber. The solution involved proper selection of components and materials that are compatible |

Frequently asked questions

If you are moving relatively low weight <10kg items around, then direct drive will be smoother, more accurate, high response, and lower temperature. If you have a big mass, then you probably want gearing to keep the size and weight of the stage down.

Very confusing terms, accuracy is how well you move to a place in space. Resolution is how places in space you can move to. It is entirely possible to have higher resolution than accuracy.

Ideally you would like an analog sensor that has infinte resolution. This will provide the best servo bandwidth. Unfortunately, analog sensors have issues with drift do to environmental changes. When going digital it is always advised to get a much resolution as the controller/drive can handle based on the rotating speed. This provides the best feedback signal and most robust control.

Yes, most motor driven rotary stages can hold a position, even against a load. It will take power to do this and without moving, efficiency is zero, so holding will create heat. It is best to upsize the torque output of the stage to handle this condition.

It is best to select a system that is vacuum rated. There are too many components like the motor, encoder and bearing grease that need to be considered when operating in a vacuum.