Sierramotion Specializes in Motors and Actuators for Semiconductor Equipment, Medical Devices, Precision Optical Systems and Space that operate in vacuum environments, (down to 10-9 ). Traditional motors, actuators, and their electronic controllers are not compatible with vacuum environments without major design and material changes.

There are several areas of concern when operating in a vacuum environment.

- Material selection: magnets, metals, potting materials, epoxy, and other low outgassing components.

- Hermetic sealing: laser welded enclosures, sealing magnets, potting materials and methods.

- Hydrogen environments: magnets do not like these environments and need to be enclosed.

- Wide temperature ranges: dissimilar material CTE differences need to be considered.

- Helium leak testing: requirement and methods to insure a hermetic seal at the vacuum level.

- Thermal modeling: operating in vacuum results in very different thermal ratings.

- Wire feedthrough selection: critical for stator assemblies and other electronic connections.

- Motion through a chamber wall: motors, magnetic couplings, and actuators can be designed to operate through the barrier of a vacuum chamber.

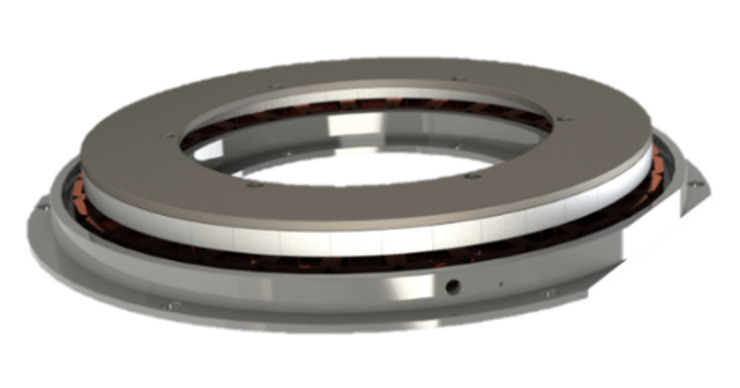

Sierramotion designs and manufactures motors and actuators including the modular axial flux motor kit below. This magnet ring is hermetically sealed by laser welding and leak tested to 10-9 atm cc/sec, it remains inside the vacuum chamber. The coil assembly resides outside the vacuum chamber in atmosphere. These axial flux motors are customized to the size and torque and made in the US.

Figure 1 – Sierramotion Axial Flux Motor Kit

When the project requires a complete motor or actuator operating in vacuum, sealing of the electrical portion of the motor is required. Similar methods of materials selection and hermetic sealing are used. A vacuum rated feedthrough is also used for any power and sensor wiring.

Sierramotion is a US based supplier of customized motor, actuator, and mechatronic solutions. The engineering team has more than 25 years of direct experience with motor design, thermal design, mechanism design, and design for special environments.

Contact us today to discuss your project.